Regarding the most important parts of the product creation process, fused deposition modeling printers are a high priority for the planning phase. This printing process is normally the first kind many people think of when they hear the phrase “3D printing.” As the first step in the planning phase for several projects, it’s good to know the top four industry uses for FDM printers.

Building Prototypes

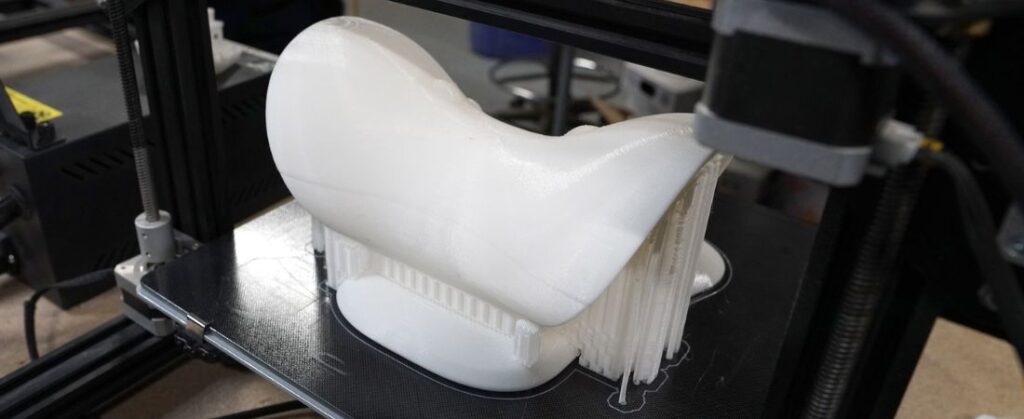

A working model for a product is important when finding any underlying kinks before beginning the production process. Prototype building is relatively easy with this printing process. While it does not implore the most advanced techniques for this technology, it is necessary to have an inexpensive process for design testing.

Creating Models

A visual model for future projects is helpful when discussing critiques or introducing the model to others. The more detailed the model of something, like a custom-designed home, the easier it becomes for the client to request changes. This ease of use allows for faster adjustments with a higher chance of customer satisfaction.

Material Testing

The FDM 3D printing process is a great way to test the strength and stability of certain materials. Different finishes are sometimes required for builds, but the material’s flexibility is greatly appreciated. Normally, thermoplastics are used to create most objects via FDM printing. However, it is not exclusive to plastics, letting people try different building methods.

Lower Costs

Producers in the automotive and medical industries will likely profit greatly from FDM printing as more advanced builds become available. The costs are greatly reduced by using 3D-designed parts for niche items and machines. Large industries that rely on difficult-to-build parts benefit the most from 3D printing. As this technology becomes more widely available, production and item costs also decrease.

3D printing is an amazing technology that allows companies to create products without relying on long wait times for intricate components. These factors improve with printing technology, from saving time to reducing costs. It’s good to know the top four FDM printing industry uses for insight into how they play a role in future developments.