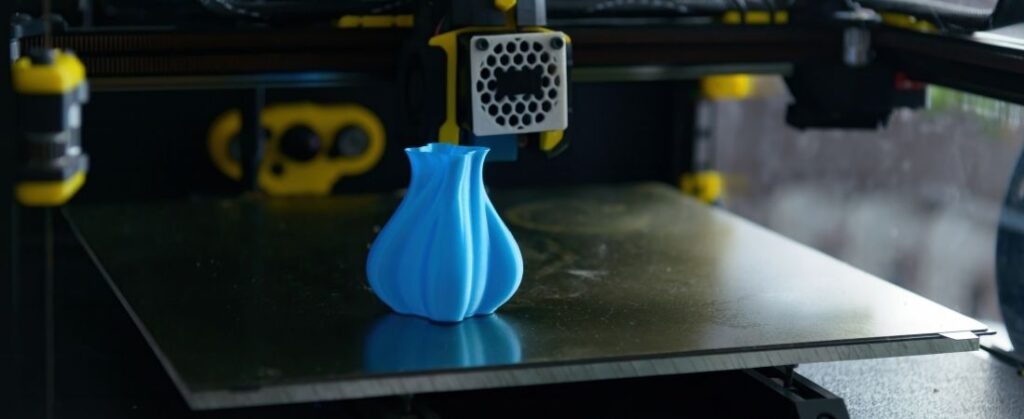

Plastics are frequently the first material that comes to mind when people think of 3D printing. Other materials, such as metal and ceramic, are available, but polymers still account for the majority of the 3D printing business. PLA and PETG are two of the most popular of the numerous materials that fall under this category. These two materials are manufactured into filaments that can be used by both beginners and experts with FDM printers and are known for their simplicity of printing. Despite the fact that they are identical in many aspects, the two strands have substantial distinctions. Here are some of the key differences between PETG and PLA filaments.

Characteristics

One of the most significant differences between PLA and PETG is the manufacturing process. PLA is distinguished by the fact that it is created from renewable and natural raw ingredients such as corn. It is also biodegradable under the right conditions, making it a popular choice for individuals looking for environmentally friendly, long-lasting materials. PETG, on the other hand, is well-known for being made of PET, a common thermoplastic. Glycol (G) is added to PET (Polyethylene Terephthalate) at the molecular level to make PETG. PETG is stronger and more durable than PET, and it is also more flexible for 3D printing, preventing it from becoming brittle when printed.

Ease of Printing

PETG is also one of the simpler materials to print with, albeit it is not as easy to work with as PLA. PETG also does not require a closed chamber, which is a big plus. PETG, on the other hand, necessitates a heated printing bed due to greater temperature requirements, thus limiting the printer options for some customers. PETG prints at a higher temperature than PLA, requiring an extrusion temperature of 220° to 260°C for best printing results. In addition, the heating bed temperature should be between 75 and 90°C.

Properties

If you’re looking for a material with good physical qualities, PETG is a better choice than PLA. Unlike PLA, PETG is resistant to water, chemicals, and fatigue. It’s also more durable and less stiff than PLA. PETG is commonly thought of as a cross between ABS and PLA—that is, it combines the best aspects of both to some extent. PETG, for example, is more flexible than ABS and stronger than PLA (but weaker than ABS) (though less flexible than PLA). As a result, PETG is a popular material since the shortcomings of both materials are mitigated inside it. PETG is also stiffer than PLA, which has its own set of advantages, particularly in industrial applications.

We hope you have enjoyed our article covering the key differences between PETG and PLA filaments. If you are looking to utilize a SLS 3D printing process for your next modeling project, be sure to reach out to Tangible Creative today!