Today’s businesses rely on mass production to reduce prices and improve ROI. However, if a company has limited resources and a strict schedule, it may be better to limit the scope of manufacturing to a smaller volume.

Low-volume manufacturing provides greater flexibility and faster time to market. The processes used significantly influence production outcomes. Here are the essential things to remember when looking at FDM versus injection molding for low-volume manufacturing.

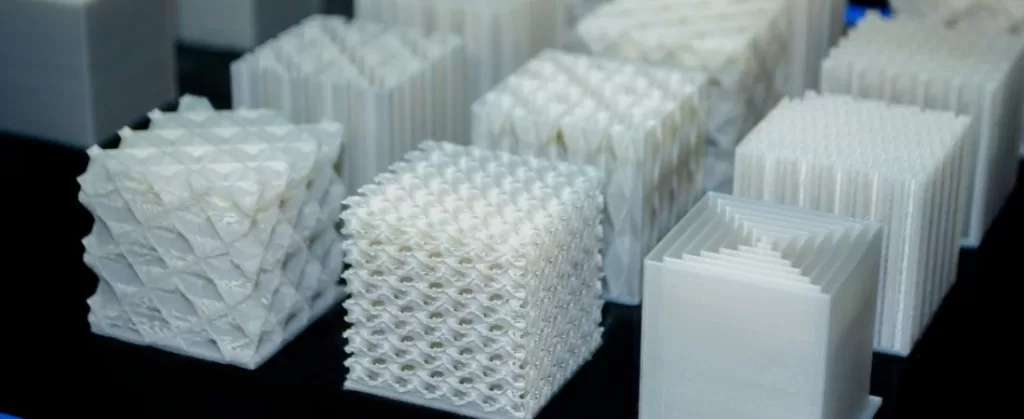

Complexity of Parts

Depending on how complex the parts you need are, FDM manufacturing may not be sufficient for your needs. Because injection molding results in greater detail, it works better for items that require more detail. Higher dimensional accuracy means parts can be designed for more specific purposes.

However, if your parts don’t need to be as intricate, FDM 3D printing can ease the manufacturing process while using fewer materials. FDM printing allows you to order fewer batches than in injection molding, leaving you with less unsold product.

Iteration Time

Another big difference between FDM and injection molding is the time it takes to iterate over designs and develop something you’re happy with. Injection molding requires manufacturing molds from scratch, which can take time and become costly if you must make changes.

FDM 3D printing, on the other hand, makes it easier to quickly iterate over designs. One approach is to use FDM to get the product exactly right before switching to injection molding once it’s scalable enough for mass production. You can even hire a third-party FDM 3D printing service to simplify the process.

Cost Per Unit

Due to their manufacturing process, FDM and injection molding have significantly different costs per unit of production. Traditional injection molding is more expensive when producing fewer parts, making it less ideal for low-volume manufacturing.

FDM is much cheaper when producing fewer parts, so long as they meet your expectations. However, the cost of 3D printing doesn’t scale effectively, so if you’re gearing up for higher volumes, it may be beneficial to use injection molding instead.

Ensure Your Manufacturing Process Is as Efficient as Possible

Whether you use injection molding or FDM 3D printing depends mainly on the number of products you plan to produce. Knowing the differences between FDM and injection molding for low-volume manufacturing is essential to improve efficiency and reduce costs. So long as FDM can print the parts you need, it’s probably a better option for low-volume manufacturing.